The only purpose of BPM is to improve business process performance.

If, in the midst of all of the words, frameworks, methodologies, and technologies, processes are not changed for the better, then the whole undertaking is a poor investment. The theories of process-based management rightly condemn as waste anything that is not adding value and improving performance, and this must also apply to the whole concept of BPM itself.

If BPM is not about improving the performance of organizations and achieving strategic organizational goals, then what purpose does it serve? The ‘process of process management’ must be held to account just like every other process. Note to process practitioners: we set the rules and must be prepared to live by them.

We sometimes lose sight of this basic premise in all of the words and work in the BPM arena. Processes must be improved and we must be able to prove, not just assert, that this is so.

The Gap

Process performance gaps should be central to all of our BPM activities. Effective process-based management is about being continuously aware of the gaps between actual and desired process performance, and doing something about closing the gaps in order of priority.

Models and methodologies are important, but BPM comes down to the deceptively simple requirement to know the performance gaps for the key processes and be continually seeking to close them.

Since it is an organization’s business processes that are delivering value (products and services) to customers and other stakeholders, we can only say we are seriously trying to optimize organizational performance if we are focused on closing process performance gaps.

This is not a trivial task, but neither is it so difficult as to excuse inaction. In any case, difficult or not, it is mandatory if we are to optimize the creation, accumulation and delivery of value across the organization.

Defining The Gap

Any process that is deemed important enough to be actively managed (and some processes are more important than others), needs to have a Process Owner. The concept of process ownership generates much debate. I think it is quite simple: the Process Owner role (or whatever you want to call it) is not responsible for process performance, but is accountable for taking effective action when process performance is out of its acceptable range or trending in that direction.

The Process Owner need not understand the minutiae of the process operation, but must be conscious of the performance gap and what short, medium and long term actions are required to manage the gap. The Process Owner defines and manages the process performance gap.

Process performance gaps might be defined in many ways. It would be useful though to have a consistent framework across an organization for thinking about process performance. The development of a consistent and ubiquitous body of knowledge about process management and improvement, at least within a single organization, is a prerequisite for high levels of BPM maturity.

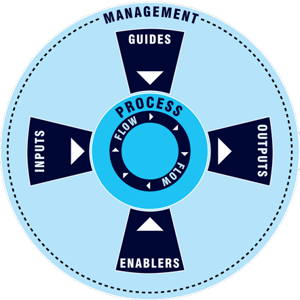

As mentioned in previous articles, there are six perspectives of process performance that provide a balanced view of a process, taking into account both the needs of customers and other external stakeholders, and the equally real needs of internal stakeholders. To briefly recap, the six process perspectives are defined as follows.

- Inputs: all that is taken into a process and transformed into outputs.

- Outputs: the results of process execution – the value delivered by the process.

- Guides: things that guide or constrain the transformation of inputs into outputs.

- Enablers: people, technology and facilities used to transform inputs into outputs.

- Flow: detailed activities within the process that develop and deliver the value.

- Management: governance of all aspects of the process; oversight of the other five process performance perspectives.

In thinking about inputs, outputs, guides and enablers, we treat the process as a black box. We don’t worry about what is going on ‘inside’, but focus on the context in which it is working. Then we make the process a glass box and look inside to see what is happening in the detailed flow. Lastly, we consider how all aspects of the process are being managed.

In thinking about inputs, outputs, guides and enablers, we treat the process as a black box. We don’t worry about what is going on ‘inside’, but focus on the context in which it is working. Then we make the process a glass box and look inside to see what is happening in the detailed flow. Lastly, we consider how all aspects of the process are being managed.

These six process perspectives provide a consistent framework for defining process performance and, therefore, the gaps. We may not conclude that measures are required in each perspective, but the final measures will come from one or more of these perspectives.

Figure 1: The Six Process Perspectives

Measuring The Gap

Everybody agrees with the idea of continuous improvement, but organizations are often not so good at continuous measurement. The other side of the continuous improvement coin is to be continuously finding things that don’t work as well as they might, and that can be challenging, perhaps even career limiting, in some organizations.

For those processes deemed important enough for active management, and there will be many of them,effective process performance measures must be defined.

Determining the correct, the vital few, measures and their measurement methods is fundamental to the whole idea of process performance management. It is also ignored by too many organizations or put aside as ‘too hard’, making a nonsense of the whole idea of process-based management.

Ultimately we must ask whether we have a viable set of the minimum number of important measures of actual process performance about which we have key stakeholder agreement, and for which we have a measurement method that can cost-effectively gather objective, accurate data against a well-defined target.

Closing the Gap

Discovering processes, defining measures, collecting, collating and reporting the data are all necessary but not sufficient steps. Our purpose must be to close the gaps, not just identify them and learn to live with them, or hope they will go away.

For a particular process the opportunity for analysis and redesign may not arise very often. It is therefore important to do everything possible to ensure that the analysis discovers, not just all of the problems and opportunities and their causes and constraints, but also discovers the very best options for change. Completing a detailed analysis of the current situation only to then accept the most obvious and perhaps mediocre changes is another expensive waste. If we are doing process analysis properly then, at least occasionally, the process improvement results should be remarkable.

In Summary …

Effective BPM is about thoughtfully defining, measuring, and closing the gaps in the performance of key business processes. If this is not the ultimately measured and demonstrable outcome, then all else has been a waste.

17 September 2014 saw the passing of Eiji Toyoda, a former President and Chairman of the Toyota Motor Corporation. More importantly, in collaboration with Taiichi Ohno, he developed the core concepts of what later became known as the 'Toyota Way', which is still the gold standard in continuous improvement. Eiji Toyoda said1 "Our workers provide 1.5 million suggestions a year, ,and 95 percent of them are put to practical use. There is an almost tangible concern for improvement in the air at Toyota." That’s what I call ‘minding the gap’.