Everybody says it’s important. Not so many do it well. Everybody promises to do better. We still end up with too many question marks.

For Eratosthenes in Alexandria, as for modern managers anywhere, measurement is important. Perhaps also complex and difficult. We’ll often be measuring something intangible. It might be difficult to take an independent measure to build confidence levels. Occasionally we might even need to invent a new measurement method to gain the needed data.

Measuring process performance is fundamental. Whether our intent is pragmatic process improvement or the more holistic goals of process management, we must measure process performance. The whole point of being process centric is to improve organisational performance. Whatever else we are doing, if we are not doing effective process performance measurement, then we certainly aren’t doing process management, and how would we know if we are doing process improvement?

Measurement is not a new topic. Others have commented on the importance of process measurement in previous BPTrends publications, notably, Gina Westcott in October 2008 and Paul Harmon in May 2008. Search the BPTrends website (www.bptrends.com) for these and other writings. In this paper I want to explore some the practical issues in establishing real process measures, capturing current values, and setting targets.

Working through process improvement projects, review teams often find it difficult to determine an effective measure or a target value for such a measure. The documentation of a process improvement project can therefore end up littered with question marks. Questions about the measurement of process performance must be resolved. Question marks in diagrams, models, and tables have a habit of staying around right to the point where they are deleted and forgotten. This is no substitute for doing the (sometimes hard) work of creating a coherent and effective set of measures.

Here’s a first piece of practical process advice: Ban the question mark! If you can’t work out the measures, values, and measurement methods, you haven’t truly engaged with the process. The most important aspect of process understanding is real knowledge about the critical few measures that really track performance. This will also be the key predictor of process improvement and management success.

Sure, there are always practical constraints about what data is available, how much it will cost to gather, and the elapsed time available in which to make process improvements. I’m not suggesting we make a career out of looking for some perfect measure. What I am suggesting is that we must engage with the challenge of finding practical and pragmatic process measures if our process work is to have any value.

Measure What?

Everything we ever measure is about one or more of time, cost, and quality, the triumvirate that measures our lives. For process measures, there are two aspects that are important. We need to have measures of process, not just functional, performance. We need to consider from whose perspective we should be measuring process performance.

The best process measures are often a bit quirky. They look and feel different from traditional functional measures but are immediately recognisable as being effective measures of end-to-end process performance. Amazon CEO Jeff Bezos gives a great example. If you run an online business you actually don’t want to have personal direct contact with customers. Customers don’t contact Amazon unless there is a problem. So they measure the number of customer contacts per unit sold and look to see that number going down. Other interesting process measures include

- time to profitability for a new product or service

- ratio of bouquets to brickbats

- percentage of internally generated waste that is reused (one of Henry Ford’s favorites)

- ratio of repeat to new business

- cost per process execution

- defection rate (customers going to a competitor)

- number of customer contacts per transaction.

These sorts of measures are qualitatively different from traditional functional measures that often have more to do with project than process management.

From whose perspective should we be making measurements?

I was travelling recently, and my flight was cancelled. The airline put me (and my luggage) on the next flight and upgraded me. Lots of smiles all round, and I imagine they thought they had done a great job. No smiles from me though. I missed an important meeting. If the airline gave themselves positive marks for that transaction they are kidding themselves. In that case, their measurement system would be so artificial as to have no contact with reality (mine or theirs).

Processes are the way organisations produce value for their stakeholders. We need to measure performance from the perspective of all the important stakeholders, not just from the internal perspective.

For the effective analysis, improvement, and management of any process, we need a well- defined set of the critical few measures that reflect and forecast process performance. Ultimately, we construct a measurement architecture to shadow the process architecture, giving a comprehensive set of measures that are horizontally and vertically aligned.

Getting Process Measurement Wrong

In an article in Sloan Management Review in March 2007, Michael Hammer described The 7 Deadly Sins of Performance Measurement. He described the general measurement sins of vanity, provincialism, narcissism, laziness, pettiness, inanity, and frivolity. We can apply those to the more specific subject of process performance management.

- Only using measures that make the process (and us) look good hides the problems. Measures should reflect areas where we want improvement.

Provincialism. Don’t let organisation boundaries drive process measure selection. Cross functional processes must have cross functional measures.

Narcissism. It’s not just about you! Include measures from the process customer’s point of view. The requirements of all key stakeholders should also be included in the process measures.

Laziness. When deciding what the best process measures are, don’t fall back on existing measures just because they are familiar and easy.

Pettiness. Look for measures that reflect what is really important – the critical few versus the important many.

- A set of measures sends messages about what you think is important. Think about those messages and ensure they are aligned with other strategic messages.

- Be serious about process performance measurement. Hold someone accountable for each measure.

Getting Process Measurement Right

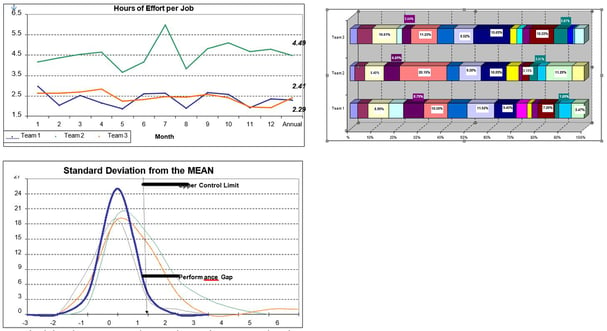

At the ProcessDays conference in Sydney a few years ago, we saw a great case study presentation by the Shared Service Agency of the Queensland Government. The Shared Service Agency provides a range of financial and administration services to 70,000 customers in 19 agencies of the government. Process improvement and management are concepts built into its business model. The agency’s success is dependent on its ability to create, improve, and manage common processes.

Many process improvement projects are underway within the agency. The presentation focused on a particular project to look at the recruitment processes. I won’t go into the details of the case study here except to highlight their dogged commitment to measuring process performance.

Reliable data, or at least data that everybody could believe in, wasn’t always available. As shown in these diagram aboves, a lot of effort went into capturing and analysing process performance data. The details of these particular diagrams aren’t as important as what they signify. The process improvement project team was committed to having a sound measurement framework for process improvement and ongoing management. This was not a simple count and a few averages. In this case, collecting the data involved significant effort in surveys and observation as well as the use of computer generated data. Of particular importance was the ability to compare performance numbers across three teams executing the same process.

The results of this process improvement project were significant and a great demonstration of the power of process thinking. Key outcomes were improved service delivery, standardised processes, and a 22% saving in direct labour costs.

In summary, here are some things to keep in mind when assigning measures to processes:

- Don’t confuse process measures and functional measures. Cross functional processes require cross functional measures.

- Processes produce outputs for stakeholders. Measure the degree to which the process meets stakeholder requirements.

- Someone must own process performance. Create a measurement-friendly culture in which accountability is an accepted part of day-to-day operations.

- Build credibility into the performance measures. Remove opportunities for anyone to challenge the need for change by calling into question the validity of the performance measurements.

- Design the measurement methods as well as the measures. Where will the data come from? Who will do the analysis? How will the information be reported? Can the cost of collection, analysis, and reporting be justified?

- Look to measure things that go wrong. The purpose of measurement is to track performance. We should be more interested in things that go wrong than in things that go right. [Of course, we want to understand what is working well and encourage behaviours that give rise to good performance. However, organisations which are not actively seeking to uncover problems, don’t find them. As always it’s about balance. I’d tip the balance in favour of continuous improvement and for that to happen you have to be continuously finding things to improve.]

- Don’t just map your existing measures onto new definitions of process. If the process modeling and analysis is new, then it is unlikely that your existing measures will be a complete set of process measures.

- Be serious about process performance measurement. Ban the question mark!

I’d love to hear about your examples of effective process performance measurement. Feel free to contact me.

(Originally published in the column Practical Process at www.bptrends.com)